Colors

Available in a choice of 20 Standard colors to color coordinate or brand your containers with company colors. Color selection is available in virgin plastic material only; recycled plastic material comes in black only.

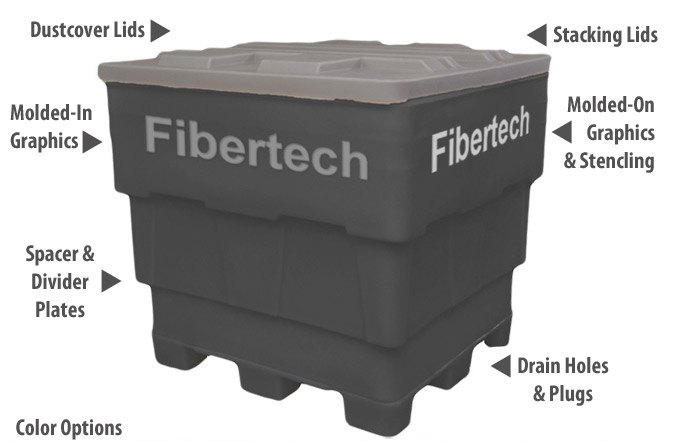

Fibertech added features and accessories to help maximize your plastic bulk containers capabilities for your business. By labeling and color coordinating your combo bins it makes organization and operations more easily defined in your facility.

Custom material handling containers offer material handling solutions that make your business more efficient and make your life easier. Personalize your bulk bins with molded-in graphics or special colors. Our reusable shipping containers are durable so that once you have chosen your material handling solutions, you are done for a long time. Customizing the bulk bins with divider plates and drain holes eliminates a secondary process to which our bulk containers can do in one. Lids protect product contamination and/or for the ability to stack shipping containers on-top of one another.

Available in a choice of 20 Standard colors to color coordinate or brand your containers with company colors. Color selection is available in virgin plastic material only; recycled plastic material comes in black only.

Black or White stenciling is available on all Fibertech containers. Logo stenciling also available, please contact us for quoting.

Your logo will last as long as the reusable shipping container. The mold-in process embeds your logo, or design, into the plastic resin during the molding process and protects it with a plastic layer. With mold-in graphics, your logo won’t fade, crack, chip or peel.

The antimicrobial protection works to reduce microbial growth on the surface of products, ensuring they remain cleaner and fresher in-between regular cleanings. Once molded into a plastic product, antimicrobial protection cannot be washed off nor does it wear away over time. The antimicrobial additive in plastic molded products does not affect the gloss or matte surfaces, color, or durability. This material and process combination provides ongoing protection for the expected life of the plastic molded product.

These permanent graphics are applied after molding, using a secondary heat source. The heat creates an unbreakable bond by encapsulating the graphic. They are permanently fused directly into the outer surface after the part has been molded or formed.

A stacking lid is molded to be stronger and heavier to support the stacking of full containers on top of each other to maximize the storage of materials.

A dustcover lid is molded to be lighter as it is used as a cover for the plastic bulk containers to protect contents from contamination.

Plates are used to separate materials from one another in the same container.

Drain holes support an ease of cleaning of our combo bins and plugs help keep materials in when not draining.